Tyre Skiving Knives

Price 50 INR/ Piece

Tyre Skiving Knives Specification

- Product Type

- Tyre Skiving Knives

- Material

- Steel Alloy

- Automation

- Manual

- Function

- Repair

- Dimension (L*W*H)

- Varies as per design

- Weight

- 100-250 Grams (g)

- Color

- Silver, Metallic

Tyre Skiving Knives Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Main Domestic Market

- All India

About Tyre Skiving Knives

We are recognized as one of the trusted manufacturers, exporters and suppliers of a broad range of Tyre Skiving Knives. These knives find their best use in tyre repairing shops and centers for tyre skining. Under the stern supervision of our diligent experts, offered knives are precisely manufactured in line with the set industry norms using quality approved nickel alloys. Moreover, our valued clients can avail these Tyre Skiving Knives in varied dimensions at reasonable prices.

- Sharpness

- Easy to use

- High endurance

- Resistant to corrosion

- Extra Curve Skiving Knife

- Round Point Flexible Skiving Knife

- Taper Skiving Knife

Advanced Blade Engineering

The Tyre Skiving Knives are available with either straight or curved blades, allowing users to choose based on specific tyre repair needs. Every blade is precision-ground, ensuring clean, controlled cuts and a smooth finish during skiving processes. The steel alloy material and custom hardness provide lasting performance, even in demanding applications.

Versatile Application and Compatibility

These knives are suitable for use in most manual skiving tools, making them a practical choice for workshops, repair centers, and tyre manufacturing units. Their rust-resistant, polished surface ensures longevity, while varied dimensions accommodate a wide range of repair scenarios, from minor punctures to extensive retreading work.

FAQs of Tyre Skiving Knives:

Q: How are Tyre Skiving Knives utilized in the tyre repair process?

A: Tyre Skiving Knives are used to precisely cut away damaged rubber or prepare the tyre surface before applying patches during repair. Their sharp, precision-ground edges allow technicians to remove material cleanly, ensuring proper adhesion of repair compounds.Q: What types of blades are available for Tyre Skiving Knives?

A: Both straight and curved blade types are offered, enabling users to select the most suitable knife for the specific contours and depths required in tyre skiving tasks.Q: When should Tyre Skiving Knives be replaced?

A: It is advisable to replace the knives when the blade becomes dull or shows signs of excessive wear. Regular inspection ensures reliable performance and preserves tyre integrity during repair.Q: Where can these knives be used?

A: Tyre Skiving Knives are compatible with most manual skiving tools and can be used in automotive workshops, tyre repair centers, and manufacturing facilities focused on tyre maintenance or refurbishment.Q: What is the manufacturing process of these knives?

A: The knives are crafted from high-quality steel alloy, ground to a precise edge, hardened to 58-62 HRC, and polished to achieve a rust-resistant finish. This process ensures durability and optimal cutting performance.Q: How does the rust resistance benefit users?

A: Rust-resistant knives maintain their sharpness and structural integrity over time, reducing maintenance needs and extending the tools service life in varied working environments.Q: Are customizations available for specific requirements?

A: Yes, Tyre Skiving Knives can be customized in terms of size, blade type, and packaging according to distributor or user specifications, making them suitable for distinct industry demands.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tyre Repair & Service Tools Category

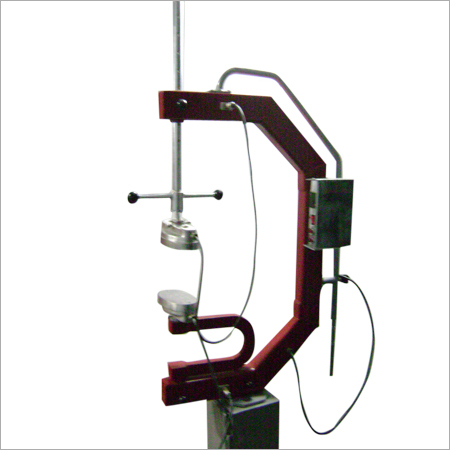

Tyre Spreader & Repairs Stand

Price 10000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Tyre Spreader & Repairs Stand, Other

Material : Steel Alloy

Automation : Semi Automatic

Function : Retread

Radial Tyre Repair Kit

Price 200 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Radial Tyre Repair Kit, Other

Material : Steel Alloy

Automation : Manual

Function : Repair

Hand Held Pneumatic Tire Spreader

Price 250 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Hand Held Pneumatic Tire Spreader, Other

Material : Steel Alloy

Automation : Manual

Function : Repair

Universal Truck & Tractor Spotter

Price 25000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Tyre Repair Machinery

Material : Steel Alloy

Automation : Semi Automatic

Function : Retread

|

VIDYA DISTRIBUTORS & AGENCIES PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry